| If you need Hot Foil Stamping type for your Kingsley Machine, click on the photo above and it will take you to a showing of the Hot Stamping Letters we are currently running. |

| Leather Embossing Leather Imprinting Leather Hot Gold Foil Stamping, Leather Personalizing Leather Engraving Monogramming Leather Engraving Embossing Machines How to Provide Excellent Leather Monogramming Engraving for Bespoke Customers Foil Leather goods being imprinted with monograms or names, even when using a good quality synthetic gold foil, are all subject to the acids used in tanning the leather and to the waxes used in the final process to make the leather have a rich luster. This can turn the foil green, or cause the foil not to stick to the surface of the leather leaving spots where there isn't any color showing in the imprint. In addition leathers are waxed or treated to make them look shiny. This wax or treatment blocks the foil from sticking to the leather. We suggest you consider cleaning the imprint area prior to doing any monogramming or imprinting. In the shop we use Windex or Alcohol Prep Pads to attempt to remove the waxes and chemicals and leave the printing surface open and receptive to the imprinting and the foil. There will always be some spoilage and loss when doing this type of work, as the imprinter is unaware of what the tannery or others have done to treat the leather. Try a sample before embarking on your project to help avoid grater losses. If your imprint is a bit blurred you many have held the handle down to long (dwell) pressed to hard, or have the temperature over 225 - 250 degrees F. If the imprint is incomplete or missing places where the gold did not stick, the temperature may be to low or the leather may need to be re-stamped or was not cleaned prior to imprinting. It is possible to re-stamp the product IF the item has NOT moved from under the stamping area. Hold the fixture in place and do not let it move. Other options, for books for example, are to use clamps or other devices to hold down your item under the stamping head so it does not move during the imprinting operation. Practice first and many times to get the feel for imprinting leather, it will be well worth your time. We do not use the foil feed when imprinting leather and suggest you consider not using it either. When the foil is installed in the machine, it blocks the operator's view of the imprint area. It is vital that you see the imprint area and not move the item until you are confident the imprint is well done. In addition, we find the foil drags on the hot type, due to the stamping process involved in doing leather, causing the foil to be what we call, "heat treated" and resulting in blurred and filled in imprints. Loading the foil will not allow you to "Blank Stamp" prior to "Laying in" the gold. We find it best to Blank Stamp first then cut a small piece of foil off the roll and place it directly on the substrate and then place the imprint or "Lay in the Gold". Read about Blank Stamping below. The Surface Must be Level The surface must be level and solid underneath the item being imprinted. Items such as wallets, day runners, bags, purses or other items that have zippers, stitching, rivets, brass hardware, folds, pockets, writing implement holders, pace for credit cards or anything that would keep the item from laying Absolutely Flat under the head will cause the imprint area to be uneven and will result in a poor imprint. We place a hard cushion board inside some items to create a flat surface on the face to be imprinted. You will need to stuff the item and "make it ready" to be imprinted so it lays completely flat under the head and parallel to the type face. If you omit this stem the imprint will be uneven. Remember you cant's stamp over the items listed above. If you try, it will cause a high spot under the printing area and result in that portion of the imprint, printing unevenly. Forcing the type down into the leather to make up the difference will cause you to smash the type. If an extra thickness of leather runs at an angle underneath the imprint area, compensate for this by inserting a small piece of cushion board to level the surface. When printing on a book, day runner or Bible, open the cover and insert only the cover under the machine. Trying to stamp a book that is closed is a recipe for disappointment. Blank Stamp First then 'Lay in the Foil' Stamp the name or monogram Without Gold (blank stamp) into the surface first to get a clear, smooth impression in the leather. In a sense, one is "Ironing the Spot to be Imprinted" with the type and making the leather ready to receive the foil. Next, place your small cut piece of foil over the imprint and re-stamp the same area "Laying In" the Gold, into the imprint. To do this you will need to hold the item in place under the head and Do Not Move It Between Stampings. Finishing Up Now, leaving the item in the machine, wipe off the surplus gold with a soft cloth, best is an old terry cloth towel that has been washed so many time it has holes in it. Be careful NOT to move the item in the machine. Take a look.... If it needs another impression because the gold did not fill in, then you still ok to do it again. Leather goods and bolts of leather come waxed many times. It is not possible to do a good job imprinting a waxed item. When you are satisfied with the imprint remove the item from the machine. To restore the luster to the leather some Leather conditioner, of your choice, can be used. We use Lexol Leather Conditioner. There is much more to the art of leather imprinting; however, this should get you started. Leather goods and hides come waxed and have been tanned with a verity of chemicals. It is not possible to do d good job imprinting on a waxed or treated item. Try cleaning them before you begin. For a detailed discussion on how to Imprint a Bible check out this web page: Bible Imprinting DO NOT FORGET to always use a cushion board under all your work!!! |

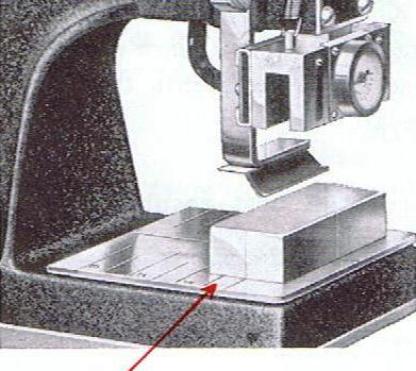

Use a support under leather to insure the area to be imprinted is FLAT, SMOOTH and with out obstructions behind the surface (zippers, folds, pockets...etc) |

| Bell Green Machine for Leather Embossing, Engraving and Hot Foil Stamping Used in Will Leather Stores |

| BELL TYPE & RULE COMPANY Hot Foil Stamping Type Machines Supplies Letterpress Printers Type Letterpress Printing |

| Copyright 2009 - 2020 David Helbock All rights reserved. david@belltype.com 310-890-2164 |

| Leather Embossing Engraving Hot Stamping Equipment Type and Services Index |

Leather Embossing Engraving Hot Stamping Monogram - BT pg 1 - welcome pg

Leather What is Leather Debossing Hot Stamping Imprinting pg 1B

Leather Embossing Hot gold Foil Stamping DEEP Type

Leather Embossing engraving Hot Stamping Type - BT pg 2

Leather Embossing - How to Emboss Leather - BT pg 7

Leather Gold Foil Stamping and Imprinting

Leather Samples Embossing Debossing Foil Stamped Leather

Leather What is Leather Debossing Hot Stamping Imprinting pg 1B

Leather Embossing Hot gold Foil Stamping DEEP Type

Leather Embossing engraving Hot Stamping Type - BT pg 2

Leather Embossing - How to Emboss Leather - BT pg 7

Leather Gold Foil Stamping and Imprinting

Leather Samples Embossing Debossing Foil Stamped Leather

| Speciality DEEP type for Leather AND raised-BASE TYPEHLODER FOR BULKY ITEMS |

| Leather Hot Stamping Machines to Fit Your Product and Production Needs |