| Kingsley Machine Operating Hints |

| We have found the above Hot Foil Printing methods useful and have used them for years with good results. The key her is to not slam the type down when printing and not to have the heat to high. In both case it cause the foundry type to ware out prematurely and the printed impression to look unsightly. Any hot foil machine will work better using a softer touch and less heat. |

A few hints to get better foil stamping results from your

Kingsley Machine

Make a few test stamping first: Before you stamp you job, hot stamp on some scrap item similar

to your job. This will allow you to check the type setting, heat, pressure, and the position of the

imprint.

If you have a "Faint Impression" hold down the handle a little longer. You can also add a bit more

pressure but if the impression is coming thought the back of your stock a lot you have to much

pressure. If the image is still faint then turn the heat up a bit. Most imprinting we have found

runs beat at 225 - 250 degrees Fahrenheit. If you need more pressure or heat you should try

another foil first.

If you have a "Blurred impression" the dwell time is to long or the machine is too hot. So don't

hold the handle down so long and or turn down the heat. We have found that to much pressure

will also cause the printing to blur.

Kingsley Machine

Make a few test stamping first: Before you stamp you job, hot stamp on some scrap item similar

to your job. This will allow you to check the type setting, heat, pressure, and the position of the

imprint.

If you have a "Faint Impression" hold down the handle a little longer. You can also add a bit more

pressure but if the impression is coming thought the back of your stock a lot you have to much

pressure. If the image is still faint then turn the heat up a bit. Most imprinting we have found

runs beat at 225 - 250 degrees Fahrenheit. If you need more pressure or heat you should try

another foil first.

If you have a "Blurred impression" the dwell time is to long or the machine is too hot. So don't

hold the handle down so long and or turn down the heat. We have found that to much pressure

will also cause the printing to blur.

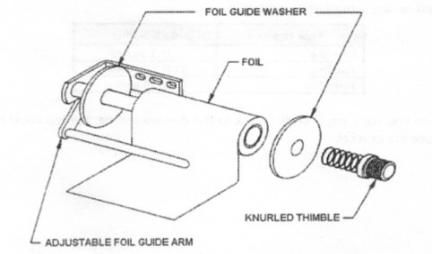

| Kingsley Machine Operating Hints The Foil Feed |

Kingsley Machine Company Foil Feeds:

Kingsley Machine Company made only a couple of types of foil feeds. We have shown them below to

assist you in learning how to use yours.

The key with all foil feed is the foil MUST NOT touch the foundry type prior to imprinting.

Foil that drags on the foundry type or dies will cause the impression to be blurry, not print and many

other undesirable things. This is a major cause of damage to the foundry type; because, operators turn

up the heat, apply excessive pressure or dwell to try to get the job hot stamped.

Make sure the foil has a cool path through your hot stamping machine and keep the heat away from the

foil. You will experience better results and ease in imprinting.

Kingsley Machine Company made only a couple of types of foil feeds. We have shown them below to

assist you in learning how to use yours.

The key with all foil feed is the foil MUST NOT touch the foundry type prior to imprinting.

Foil that drags on the foundry type or dies will cause the impression to be blurry, not print and many

other undesirable things. This is a major cause of damage to the foundry type; because, operators turn

up the heat, apply excessive pressure or dwell to try to get the job hot stamped.

Make sure the foil has a cool path through your hot stamping machine and keep the heat away from the

foil. You will experience better results and ease in imprinting.

| We are showing how the Ludlow type looks that was used in hot stamping this napkin. Using an easy release gold foil and Ludlow Slugs the printing impression is appealing. |

| When you are doing napkin imprinting or on most soft materials it is best to use a hard cushion board. Also, a hard cushion board will improve the sharpness of the imprint. |

| Kingsley Machine |

| BELL TYPE & RULE COMPANY Hot Foil Stamping Type Machines Supplies Letterpress Printers Type Letterpress Printing |

| Copyright 2009 - 2015 David Helbock All rights reserved. david@belltype.com 310-890-2164 |